Classic Cyanotype & New Cyanotype Processes

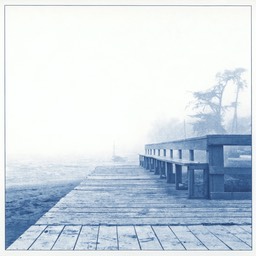

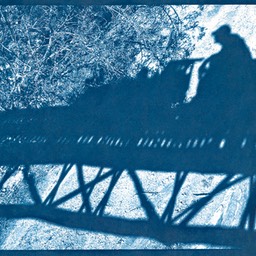

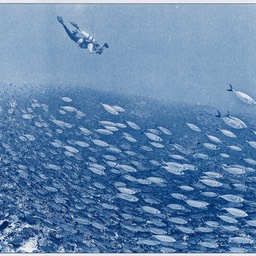

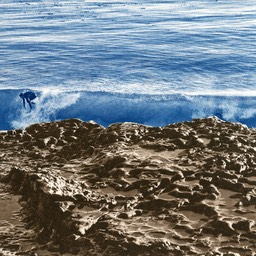

The classic, safe, affordable, indeed rather strident, Prussian Blue process. One of the more interesting plays with Cyanotype is to create images that actually work well with Cyanotype. It can be tough. Early morning before sunrise when the sky is dark blue and the scene before you is cast in a cool monotone for example. The underwater world is a wonderful aquamarine when viewed under natural light. And so it is, safe, affordable, strident, and, well, blue. The cost of the chemistry is as low as $0.02 per 8x10 print, effectively making the chemistry free when compared to the cost of the paper the image is printed on.

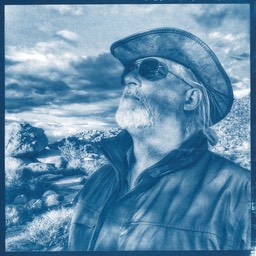

New Cyanotype is a modern, circa 1994, variation of the classic A/B Cyanotype process, invented by Dr. Mike Ware in a effort to overcome downsides of this classic process. The primary Cyanotype downsides the Ware formulation overcame are it’s tedious exposure times, ability to thoroughly penetrate into paper and cloth fibers, and issues with Prussian Blue itself washing out of the paper and leaching into the highlights during wet processing. Generally, conferring greater speed, stability, convenience and quality on the process.

Changes made to the classic formula were the replacement of Ferric Ammonium Citrate with Ferric Ammonium Oxalate and replacement of Potassium Ferricyanide with Ammonium Ferricyanide. These changes in chemistry increase cost to the sensitizer solution (90x cost increase of kit form over classic A/B Cyanotype), while increasing light sensitivity almost 4x, has no mold growth, can keep emulsion in a single-bottle solution for extended periods of time (year+), and paper and cloth absorption being greatly improved. The change from Potassium Ferricyanide to Ammonium Ferricyanide allows the image hold up well under wet processing – little image dispersion or bleeding into the highlights resulting in a dense image with clear highlights.

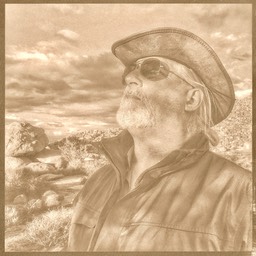

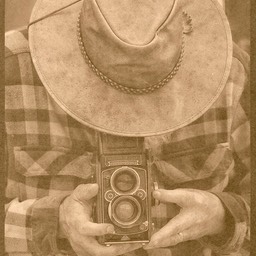

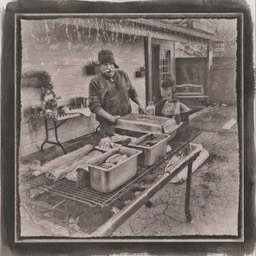

Toning a Cyanotype results in everything from a dark eggplant sepia to a rich desert patina, all pending the tannins and stage of image bleaching used. Cyanotype acts like Velcro™ with its toning process. Full metal replacement toning involves bleaching or ‘ripping apart’ the Prussian Blue portion of the image, leaving a faint yellow image behind - like ripping the loops layer of Velcro™ off the hooks layer, leaving the hooks ready to accept something else. In the case of Cyanotype, the faint yellow image is awaiting a new iron metal, generally gallic or tannic acid – pure tannic acid or tannins from strong black coffee or thick red wine. The fresher and stronger the coffee and more tannic the wine the better. Toning via tannic acid (pure or from coffee, red wine, etc.) added directly to a Cyanotype without bleaching results in a dark warm overall image. Again, care must be taken to avoid dying of the paper media itself.